1920s — 1950s

Zephyr Manufacturing Company was founded in 1927 by Harry E. Lindstrom in Kansas City, Missouri, and was first known as Acme Broom Company. Initially the products consisted of only brooms.

By 1932 the Company had outgrown it’s original building and moved to Sedalia Missouri. In 1938 the Zephyr Streamline broom was developed, patented, and placed on the market. It enjoyed immediate success and was the Company’s flagship product for many years.

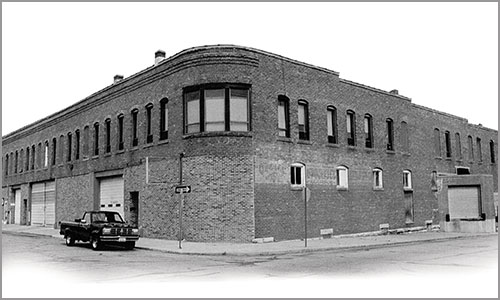

In the early 1940’s when the Company again outgrew its location, it moved to a 2 story brick building of approximately 34,000 square feet that became the Company’s office and main manufacturing facility for 50 years. Also about this time the assets and products of the Kansas City Broom Company were acquired. This company also manufactured mop products and so the Company entered the mop business. The name of the Company was changed to Acme Manufacturing Co.

As World War II required most able manpower, it became difficult to produce the quality brooms that gave Acme Mfg. Co. nation-wide fame. Therefore, the production of brooms was discontinued although the Company continued making mop products. In 1948 the production of brooms was resumed.

In 1946 the Company decided to incorporate. Since the Acme name was already in use, it was decided to re-name the company Zephyr Manufacturing as the “Zephyr” name was already well known.

In 1957 Harry E. Lindstrom suffered a stroke and passed away. At that time Robert J. (Bob) Lindstrom, Harry’s son, who began his career with the Company in 1947 assumed the responsibilities of Company President.

1960s — 1990s

In 1962, the Company purchased the W. W. Stewart Company whose products consisted of household chemicals, household gadgets, and natural rubber dry wall cleaning sponges.

In 1973 the Company acquired 3 acres for future expansion and a 12,000 square foot building was erected. All broom manufacturing and warehousing were moved to this location

In 1982 Robert retired after 35 years of service to the Company. He left behind a legacy of solid growth and expansion while also developing no less than 5 Patents on broom and mop products. His son, John, who began his career with Zephyr in 1975 became Chief Executive Officer and thus began the 3rd generation of family management.

In 1984 Zephyr made the decision to undertake a substantial capital expansion to build a complete rubber manufacturing facility in our Metalic Lane location. The existing broom manufacturing operations were moved back to the main facility and all equipment for the Stewart division were moved to the rubber facility. The completed rubber manufacturing facilities were put into operation in June of 1986.

In 1987, Zephyr purchased the assets of The Quality Rubber Co. The equipment and processes of Quality were moved to our rubber facility in 1988. The Quality Rubber Company began operating as a separate division of Zephyr with its own product line. As the original tools and chemical products had been discontinued, the Stewart name was abandoned and all sponge rubber products are marketed under the Quality Rubber name.

In July 1988 Zephyr purchased the assets of the Deshler Broom Factory in Deshler, Nebraska. This Company was operated as a division of Zephyr and sold broom and mop products mainly to the retail trades under the label Bright ‘n Clean™. This acquisition gave Zephyr the additional production capacity for broom products that was needed to sustain our growth. All existing broom production in Sedalia was moved to Deshler freeing up needed manufacturing space.

In March 1990 the assets of the San Antonio Broom Company were purchased. Additional broom and mop manufacturing equipment was moved to existing facilities and Zephyr marketed additional products under the Blue Bonnet™ name in Texas. In May 1991 the equipment of the California Mop Company of Los Angeles was purchased and moved to Sedalia. This much needed manufacturing machinery greatly increased the Company’s mop production capacities.

By 1992 Zephyr’s growth had forced it to lease additional warehouse space in Sedalia requiring it to operate in 3 locations in Sedalia plus the Nebraska factory. A more modern facility was purchased in Sedalia. This 63,000 square foot facility located on 10 acres was sound and ideally suited as the Company’s main manufacturing and distribution facility. An extensive renovation was undertaken involving major items consisting of a completely new roof, all new lighting, warehousing racks, loading docks, heating and ventilations systems, and new office facilities. In October 1992 the Company moved all of its equipment and inventory out of its 2 story building and the leased warehouse. This massive move was planned and executed by Company personnel over a one week period and resulted in no interruption of service to our customers.

In 1993 the adjoining land to the Quality Rubber facility was purchased yielding expansion space of close to 7 acres. In April 1994 the assets of the Platte Valley Broom Company in Nebraska were purchased. All the production equipment was moved to the Deshler and Sedalia facilities again increasing both broom and mop production capacities. In December 1994 the assets of Woodfield Industries were purchased giving the company a complete wood handle manufacturing production line.

In November 1996 additional equipment and renovations were made to the Quality Rubber facilities that doubled the production capacity of its sponge rubber products. In August 1997 the Company completed a 12,000 square foot addition to the Quality Rubber facility doubling the square footage of that location.

By 1998 it became obvious the combination of NAFTA, increased production costs, and low unemployment were making it difficult to continue the production of broomcorn brooms in the United States. In December 1998 the Company closed it’s Deshler Broom Facility. At the time of closure the Deshler Broom factory had operated, under different ownerships, for 108 years making it the oldest operating broom factory in North America. All broom products were then manufactured in Mexico, a trend that had started 3 years earlier.

2000s — Present

During 2000 and 2001 the Company undertook several extensive in-house design and build projects of proprietary mop manufacturing equipment. These projects increased capacity and enhanced productivity while striving to reduce any chances for workplace injuries.

In 2006 the Company emphasized its commitment to customer service and growth by establishing a second full time sales position of Re-Distribution Sales Manager in addition to our Vice-President of Sales.

In 2007 Zephyr spun-off the Quality Rubber Division into a separate company. Since the two companies represented totally different markets and products this move allowed Zephyr management to concentrate on its core Jan-San products and customers.

In 2008 Robert (RJ) Lindstrom joined the Company as a management trainee. This begins the 4th generation of family management at Zephyr.

Today, R.J. Lindstrom is company president as John has retired. R.J. looks forward to continued growth for the company that his great-grandfather started 90 years ago.

“If you look at Zephyr from the first generation to now, it’s a completely different company. You have to change with the times to remain relevant in the marketplace,” R.J. Lindstrom said. “Zephyr started out simply as a broom winding company, and now it doesn’t have any broom winders. We didn’t sell mops in the beginning, and now mops are our main product line. A lot of things have changed over the years to help make Zephyr competitive and remain in the marketplace.”